Showroom

This array of Chemical Plant Equipments is well furnished with advanced machines like planetary mixer, evaporator, hydrogenator etc. These highly durable equipments are quality tested to prove their flawless features.

This range of Planetary Mixers is well known for its homogeneous mixing process and high sped operation. Available in different capacities, such low maintenance mixing systems have long working life.

Chemical Reactors have wide applications in chemical processing and also in pharmaceutical arena. Such reactors have been ergonomically designed to meet specific production needs. Long working life and low maintenance cost are the main aspects of these reactors.

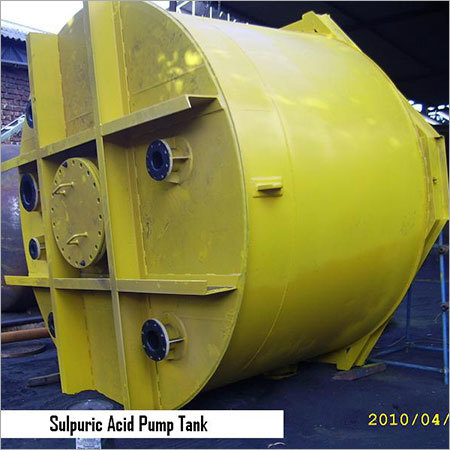

Chemical Processing Plants are used as reliable options to conduct various chemical reactions under specific operating temperature and pressure. These plants are completely protected against corrosive gases, toxic fluids and harmful chemicals.

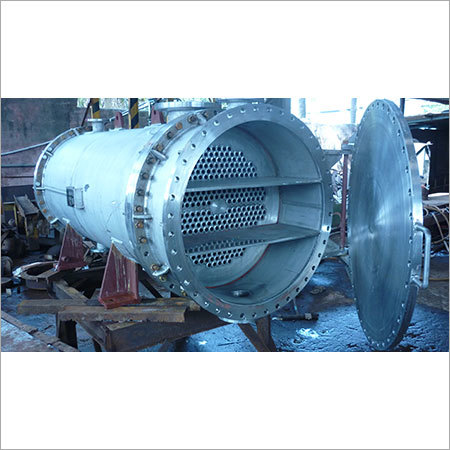

Heat Exchangers have wide applications in power generation plants, refrigeration units, natural gas processing arena and also in petrochemical field. Quick to install, these user freindly systems have long working life.

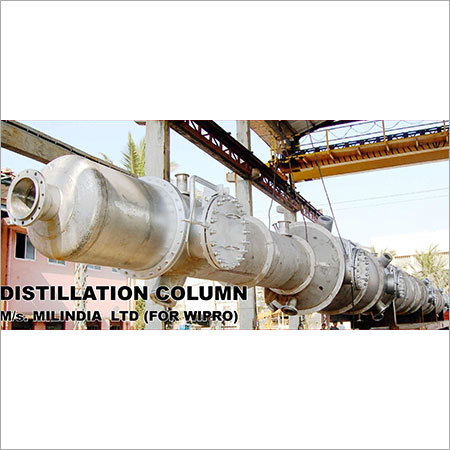

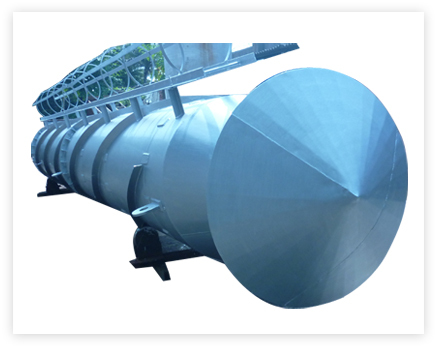

This array of Distillation Columns is well known for its ergonomic look and high production capacity. Based on production needs, such horizontal type industrial systems are offered in different capacity and design choices.

Limpet Reactors are used for managing temperature of reactants by using heating or cooling media. These reactors have welded pipes that surround these externally. Such reactors are suitable for thermic fluids having more than 150 degree C temperature.

Industrial Evaporators are used for concentration of dye intermediate, milk, fruit juices and other edible products, waste water etc. Made of 304 grade stainless steel, such evaporators have long working life.

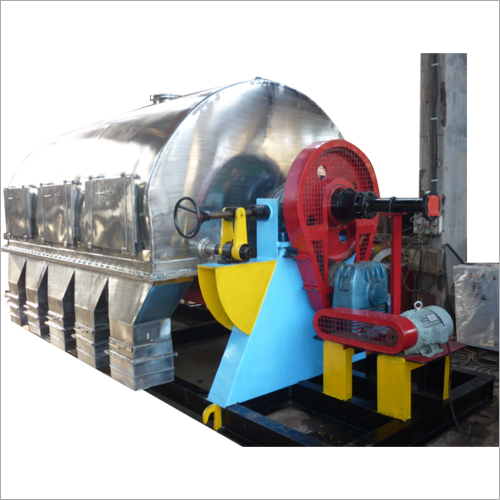

Stainless steel or carbon steel made Industrial Flakers can be availed in automatic and semi automatic versions. These high performance systems have long working life, low maintenance cost and user friendly mechanism.

Buy from us vertically and horizontally aligned storage tanks for industries, like dairy, beverage, chemical, petroleum, and water treatment. The durable and fire-resistant tanks usually made from steel are designed for safe storage and transportation, while withstanding extreme temperatures.

There are filters used in processes, like removing impurities from the extracted oil, and filtering liquids and gases, and removing organic contaminants from wastewater. These industrial filters are cost-effective, environmentally friendly, versatile, and have longer service life.

Buy from us industrial condensers for use in chemical, petrochemical, pharmaceutical, and other industries for transferring heat from a hot vapor/gas to a cooling medium, to condense the vapor or gas into a liquid. Shell and tube condenser is the most common type of industrial condenser.

An industrial dryer called rotary vacuum dryer finds use in pharmaceutical, chemical, mineral, food and other industries for drying materials under vacuum, while maintaining product quality and reducing energy consumption.

Molecular sieve in the molecular sieve dryer is a desiccant material that removes moisture from compressed air. This energy efficient dryer has high moisture removal capacity, and results in high purity air by removing oil and dust particles.

"We Have Special Offer For Bulk Inquiry, Looking For Inquiry In Large Quantities"

Send Inquiry

Send Inquiry Send SMS

Send SMS