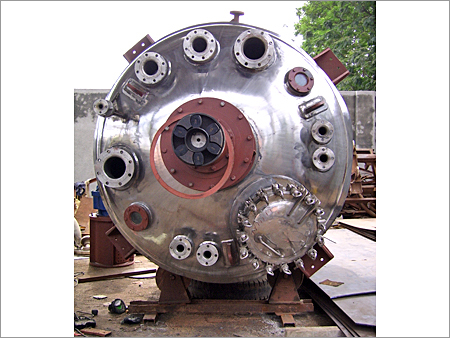

Jacketed Reactor

Product Details:

- General Use Mixing

- Material Stainless Steel

- Click to View more

Jacketed Reactor Price And Quantity

- 100000 INR/Unit

- 1 Unit

Jacketed Reactor Product Specifications

- Stainless Steel

- Mixing

Jacketed Reactor Trade Information

- 2-5 Unit Per Month

- 4-8 Week

Product Description

In traditional jackets, the second shell is fitted over a part of the vessel, making a space within which cooling or heating medium flows. The internal share is composed of baffles straight flowing in a spiral shape around the jacket and tossing nozzles, generating high turbulence throughout the duration of the fluid inoculation in the jacket. This device made from stainless steel (304, 316), Mild Steel, Hastelloy C, titanium and nickel, is used in pharmaceutical and chemical industries. Before delivery, the offered Jacketed is strictly examined for stringent compliance with Stainless Steel 304 and Stainless Steel 316 certifications of quality.

Products Further Details:

Jacketed

In Conventional Jackets, second shell is included over a portion of the vessel, creating an annular space inside which cooling or heating medium flows. A simple conventional jacket with no internal components, is optimally functional for heat transfer, given to the flow media giving an extremely low velocity generating a low heat transfer coefficient. Condensing media, like Dowtherm A or steam, is a rare as in this case the heat transfer coefficient does not count on turbulence/ velocity, but instead is contingent on the surface area, upon which the media condenses and the proficiency of eliminating condensate. Internals include baffles that directly flow in a spiral pattern around the jacket, and agitating nozzles that create requisite turbulence at the point where the fluid is poured into the jacket.

Limpeted Vessel with Closed Rigid Container is fabricated making use of stainless steel and carbon steel alloy to ensure fine finish and enduring use. The Limpeted Vessel is fitted with closed rigid container to hold liquids and gases at different pressure. The Limpeted Vessel is given in robust construction that is easier to operate. The clients can avail Limpeted Vessel with Closed Rigid Container in several sizes and shapes to meet their specific requirements.

Jacketed or Limpeted type:

-

Capacity: 100 Ltr to 25000 Ltr. In Mild Steel, Stainless Steel 304, Stainless Steel 316 Material

PROCESS REACTION VESSEL

The multipurpose industrial reaction vessel, process reaction vessel and plants offered to produce Bulk Drugs and APIs, are designed and developed focusing on the important process parameters that include cleanability & product impurity profile. Depending on the data, evaluation of the heat transfer requirements, agitation degree, space availability, pressure - temperature ratings, product properties, surface finish requirements, HAZOP Studies, corrosion allowance etc., are carried out for making available a well designed system ideal for the application.

Applications: Food Products, Chemical, Pharmaceuticals, Dyes & Intermediates in GMP & Non GMP models.

We offer the following:

-

Comprehensive GMP systems with Layout & Detail Engineering, Basic & Process Engineering.

-

In compliance with 'C-GMP' standards and requirements of USFDA and other International regulatory bodies.

-

Designed according to international codes for pressure parts

-

Internal surface finish up to 600 Grits with Mechanical / Electro-polishing with crevice-free internals to stop contamination and allow complete cleaning during product changeovers

-

Pre - insulation for hot and cold service with Stainless Steel 304 cladding

-

Condenser vapour side is detachable to easily allow manual cleaning

-

Sealing mechanisms for bearing housing to eliminate grease leakage even in a solvent medium

-

Italian Helical gearbox has optimum proficiency and Mechanical Seal for avoiding recurrent seal failure resulting in oil leakages; it is also provided with oil leakage collection chamber.

-

Different kinds of agitators, like Anchor, Helical, Propeller, MIG, Turbine, Hydrofoil and Contra mixer.

-

The Vessel, Column, Receiver & Condensers with bolted openings can be taken apart to aid in manual periodical cleaning or between product changeovers

-

The Nozzle & the Reflux line connections can be provided with Sanitary Triclamp, DIN, IDF, SMS, or flange ends as required by the customers.

-

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+