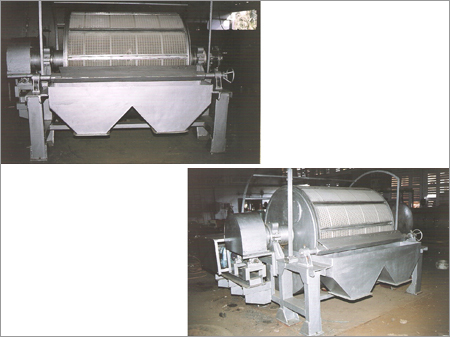

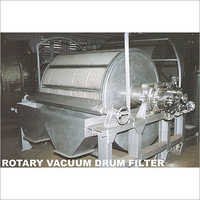

Rotary Vacuum Drum Filter

Price 100000 INR/ Unit

Rotary Vacuum Drum Filter Specification

- Efficiency (%)

- Up to 99%

- Resistance

- Corrosion resistant

- Material

- Stainless Steel / Mild Steel / Polypropylene lining

- Thermal Shrinkage

- 1%

- Working Temperature

- Up to 80C Celsius (oC)

- Application

- Industrial filtration, wastewater treatment, chemical, pharmaceutical, mining

Rotary Vacuum Drum Filter Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 4-8 Week

About Rotary Vacuum Drum Filter

Operating from our base in Mumbai, Maharashtra, India, since the year 1998, we are competently manufacturing, exporting and supplying a Rotary Vacuum Drum Filter, along with an entire gamut of reliable equipment for the chemical industry. Designed to facilitate quick and complete drying as a batch operation, this filter is suitable for drying heat sensitive material, which is generally 40-45 percent of the wet material loaded into it. Made available in capacities of 10,000 to 20,000 liters, this Rotary Vacuum Drum Filter is used for processing pharmaceuticals, organic chemicals, pasty materials, insecticides, pesticides, dye intermediates, dyestuffs and in solvent recovery applications.

Features of Rotary Vacuum Drum Filter:

- Equipped with agitators

- Quick opening discharge valve

- Breaker rods to prevent lump formation

- Shaft sealing with mechanical seals

- N2 pulse jet dust filter (self cleaning type)

| Capacity : 0.5m3 to 10.0m3 in M.S. S.S.304, S.S. 316 Material Jacketed or Limpeted type . Applications : Chemicals, Pharmaceuticals, Food Products, Resins, Dyestuffs. |

FAQs of Rotary Vacuum Drum Filter:

Q: How does a Rotary Vacuum Drum Filter work in industrial filtration?

A: A Rotary Vacuum Drum Filter operates by continuously rotating a drum through a slurry or suspension. As the drum surface passes through the liquid, vacuum pressure pulls liquid through the filter media while solids form a cake on the drums exterior. The collected solids are then discharged as the drum rotates out of the slurry zone, allowing for efficient separation of solids from liquids.Q: What are the benefits of using a corrosion-resistant Rotary Vacuum Drum Filter?

A: Using a corrosion-resistant Rotary Vacuum Drum Filter extends service life, reduces downtime from maintenance, and ensures consistent filtration performance, even with aggressive chemicals and harsh process fluids. This makes them a cost-effective solution for industries dealing with corrosive substances.Q: When is it advisable to use a Rotary Vacuum Drum Filter in wastewater treatment?

A: It is advisable to use a Rotary Vacuum Drum Filter when high-efficiency solid-liquid separation is required, especially in continuous operations or where process fluids contain fine particulates. They are particularly effective for primary sludge dewatering, chemical precipitation, and recovery of valuable solids in wastewater treatment.Q: Where can these filters be installed for optimal performance?

A: Rotary Vacuum Drum Filters can be installed in industrial plants, wastewater treatment facilities, chemical production sites, pharmaceutical manufacturing units, and mining operations. For optimal performance, these filters should be installed upstream or within process lines where continuous removal of solids is necessary.Q: What materials are available for the construction of your Rotary Vacuum Drum Filters?

A: Our filters are available with construction in stainless steel, mild steel, or a polypropylene lining. Material selection depends on the chemical and physical properties of the process fluid to ensure maximum compatibility and longevity.Q: How does the design contribute to maintaining high efficiency (up to 99%)?

A: The design ensures up to 99% efficiency by providing continuous filtration, a robust vacuum system, and adaptable filter media tailored to the application. This combination maintains a high solid capture rate and consistent performance across varied operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Category

Nutsche Filter

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel (SS304, SS316), Alloy, Hastelloy

Application : Pharmaceuticals, chemicals, dyes, food, and beverages

Working Temperature : Up to 200C

Cartridge Filters

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

Application : Industrial

Color : Yellow

Carbon Filters For Etp

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Activated Carbon, Steel/FRP Casing

Application : Effluent Treatment Plants (ETP), Water Purification, Industrial Filtration

Working Temperature : Up to 120C

Carbon Filter For ETP

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Application : Industrial

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS