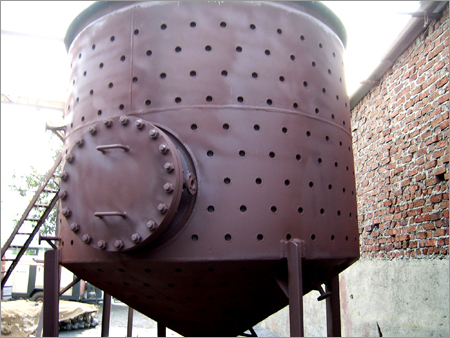

Jacketed Vessel Pipe Doublers

Price 100000 INR/ Unit

Jacketed Vessel Pipe Doublers Specification

- General Use

- Mixing

- Material

- Stainless Steel

Jacketed Vessel Pipe Doublers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 4-8 Week

About Jacketed Vessel Pipe Doublers

Eminent manufacturers, exporters and suppliers of top-notch process equipment for the industry, worldwide, we bring forth this precisely engineered Jacketed Vessel With Pipe Doublers. Manufactured from nickel, Hastelloy C, M.S., Titanium and SS (304,316), this vessel finds immense applicability in the chemical and the pharmaceutical industry. Offered Jacketed Vessel With Pipe Doublers can be made available in custom made options at a competitive price.

Features:

- Conventional design

- Optimum operational life

- Robust construction

- Hitch-free functioning

other details:

Manufactured making use of Hastelloy C, Mild Steel, nickel, Titanium and SS (304,316), this Jacketed Vessel With Pipe Doublers is applicable in the chemical and pharmaceutical industries.

More Information:

Capacity : 100 Ltr to 25000 Ltr. In Mild Steel, Stainless Steel 304, Stainless Steel 316, Material, Jacketed or Limpeted type.

Applications : Food Products Dyes & Intermediates, Chemical, Pharmaceuticals, in GMP & Non GMP models.

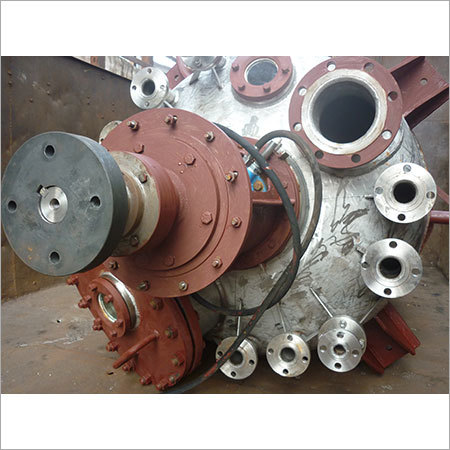

Process Reaction Vessels

Our Multipurpose process reaction vessel, industrial reaction vessel and plants for Bulk Drugs and APIs production are designed considering several Process Parameters, such as clean-ability and product impurity profile. Our experts based on the provided data analyze the following to provide an optimum system suiting customer application:

- Heat Transfer requirements

- Surface Finish requirements

- Product Properties

- HAZOP Studies

- Degree of Agitation

- Pressure - Temperature Ratings

- Space Availability

- Corrosion Allowance

We offer the following:

-

Complete GMP systems with Basic & Process Engineering, Layout & Detail Engineering.

-

Meeting 'C-GMP' Standards and strict requirements of International regulatory bodies, such as USFDA.

-

Designed as per the various international codes for Pressure parts

-

Internal surface finish up to 600 Grits with Mechanical / Electro-polishing

-

Crevice-free Internals for preventing contamination and facilitating thorough cleaning during product changeovers

-

Removable condenser vapor side to facilitate manual cleaning

-

Pre - insulation for hot and cold service with Stainless Steel 304 cladding

-

Specially designed sealing mechanisms for bearing housing for preventing grease leakage even in a solvent atmosphere

-

Offered Italian Helical gearbox with high efficiency and Mechanical Seal for preventing frequent seal failure resulting in oil leakages, also provided with oil leakage collection chamber

-

Provided with various kinds of agitators, such as MIG, Hydrofoil, Propeller, Anchor, Turbine, Helical and Contra mixer.

It is easier to dismantle the Vessel, Receiver, Column & Condensers with bolted openings to facilitate manual cleaning timely or between product changeovers.

The Nozzle & the Reflux line connections can be given with Sanitary Triclamp, SMS, DIN, IDF or flange ends, as demanded by the customer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reactors Category

C-GMP Reactor

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

General Use : Mixing

Product Type : REACTOR

Feature : High Speed, Vacuum Resistant Vessel, Hydraulic System, Vacuum Pump

Reactor Front View

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

General Use : Mixing

Product Type : Reactor Front View

Feature : High Speed

Chemical Reactor Top View

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

General Use : Industrial

Product Type : Chemical Reactor Top View

Feature : High Speed

Reactor Side View

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

General Use : Mixing

Product Type : Reactor Side View

Feature : High Speed

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free