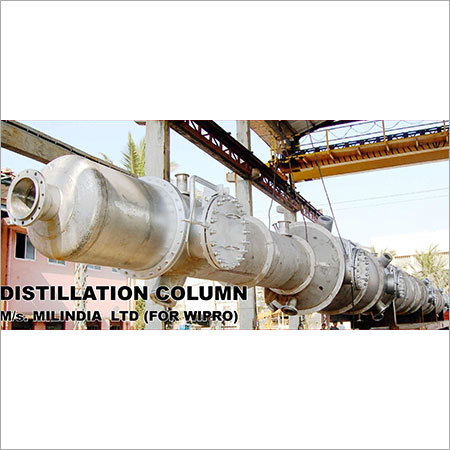

Industrial Distillation Column

Price 100000 INR/ Unit

Industrial Distillation Column Specification

- Condition

- Power

- 10-75 kW

- Product Type

- Industrial Distillation Column

- General Use

- Separation and purification of liquids

- Material

- Carbon Steel

- Capacity

- 5000-50000 L

- Weight (kg)

- 2000-12000 Kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Mixer Type

- Agitator Mixer

- Shaft

- Stainless Steel Shaft

- Drive Type

- Electric Motor Drive

- Voltage

- 380-440 V

- Motor

- Heavy duty, energy efficient

- Dimension (L*W*H)

- Custom/As per requirement

- Feature

- Corrosion resistance, high efficiency, low maintenance

- Color

- Metallic grey

- Warranty

- 18 month

- Protection Coating

- Epoxy/Paint for anti-corrosion

- Application

- Petrochemical, Pharmaceutical, Chemical, Food Industry

- Temperature Range

- Up to 350°C

- Internal Trays/Packings

- Bubble Cap, Sieve Tray, Structured Packing

- Operating Pressure

- Atmospheric to 10 bar

- Column Shape

- Cylindrical, Vertical

- Insulation

- Provided as required

- Design Standard

- ASME / DIN / IS standards

- Service Life

- 10-15 years (typical)

- Feed Inlet/Outlet Ports

- Flanged Coupling

Industrial Distillation Column Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 4-8 Week

- Main Domestic Market

- All India

About Industrial Distillation Column

With steadfast dedication towards manufacturing and exporting high performance chemical pharmaceutical process equipment for our esteemed clients from Africa, the Gulf, Sri Lanka and Bangladesh, we bring forth this promising range of Distillation Column. Accurately engineered from certified metal alloys for storing volatile liquids in petrochemical, chemical, pharmaceutical and distillation industries, this storage equipment can be made available in custom options, as per the needs of our clients. In ahead of their delivery, the offered Industrial Distillation Column are stringently inspected to assure their compliance with SS304 and SS316 standards of quality.

Products Features:

- Enhanced chemical resistance

- Low maintenance

- Superior Corrosion Resistance

- Chemical Resistance

- Temperature Resistance

- Enhanced Mobility

- Corrosion resistance

- Optimum durability

Distillation Column

With an experience in manufacturing high performance chemical pharmaceutical process equipment for customers in Bangladesh, Africa, the Gulf, Sri Lanka, our company makes available this Distillation Column. Certified metal alloys are used for engineering this equipment needed to store volatile liquids in distillation, pharmaceutical, petrochemical, and chemical industries. We can make this storage equipment available in custom options, as per the requirements of our clients. Before delivering the equipment to client, it is inspected to make sure it is in compliance with SS304 and SS316 standards of quality.

Products Features:

-

Temperature Resistance

-

Enhanced Mobility

-

Corrosion resistance

-

Optimum durability

-

Enhanced chemical resistance

-

Low maintenance

-

Superior Corrosion Resistance

-

Chemical Resistance

Material of Construction (MOC) Offered: - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), Stainless Steel 316, Stainless Steel 304, Stainless Steel 316 L, Stainless Steel 304 L, Stainless Steel 310, INCONEL, TITANIUM, MONEL, HASTALLOY, etc.

Distillation Column Specification:

-

Distillation columns are suitable for a many industries and provided in two types

-

Batch columns where the column feed is assured batch wise; the second batch is introduced only after the first batch is completed

-

Continuous columns where an arrangement for continuous feed stream is made for the distillation column, and desired outputs are achieved.

Distillation Column Operation:

We provide distillation columns based on the number of product streams they possess. These comprise columns with over two product streams. These columns are beneficial in executing the extractive distillation and azeotropic distillation. These boast of trays and packs for bringing out enhanced distillation.

- Their functionality is based on the variance in boiling temperatures of the liquid mixture components, and on recycling counter-current gas-liquid flow

- The approx. arranged temperature distribution up the column results in different mixture compositions at several heights

- While multi component inter-phase mass transfer is a general phenomenon for all column types, the flow regimes are opposite on the basis of the internal elements used.

Product details

|

Usage/Application |

Industrial |

|

Design Type |

Customised |

|

Material |

Stainless Steel |

|

Capacity |

Customize Size |

|

Brand/Make |

Sunrise Process Equipment |

|

Model Name/Number |

Industrial Distillation C |

Efficient Separation Across Industries

Our distillation columns are tailored to suit the unique needs of petrochemical, pharmaceutical, chemical, and food industries. Precision-engineered trays and structured packings optimize separation efficiency, facilitating consistent product quality and improved process yield. Adaptable insulation and advanced PLC control options ensure reliable operation regardless of process challenges.

Durability and Anti-Corrosion Features

Constructed from high-grade carbon steel and coated with epoxy or industrial paint, these columns resist corrosion in harsh operating environments. Engineered for longevity, they deliver a typical service life of 1015 years, providing dependable and economical operation for a wide variety of industrial applications.

FAQs of Industrial Distillation Column:

Q: How does the distillation column ensure efficient separation in various industries?

A: The column utilizes advanced internal configurations such as bubble cap trays, sieve trays, and structured packing. These designs enhance contact between vapor and liquid phases, maximizing separation efficiency for petrochemical, pharmaceutical, chemical, and food processing applications.Q: What benefits does the epoxy or paint protection offer for the distillation column?

A: Epoxy or paint coatings provide robust anti-corrosion protection, ensuring durability and reliability even in chemically aggressive environments. This significantly extends the columns operational lifespan, minimizing maintenance needs and saving on replacement costs.Q: When should insulation be added to a distillation column?

A: Insulation is provided as required based on the process temperature, environmental conditions, and safety considerations. It helps maintain optimal thermal efficiency, prevents energy loss, and ensures safe external surface temperatures.Q: Where are the feed inlet and outlet ports positioned on the column, and how are they connected?

A: Feed inlet and outlet ports are strategically located along the column to optimize process flow. They are fitted with flanged couplings, which facilitate secure, leak-proof connections and enable straightforward installation or maintenance.Q: What standards regulate the design and manufacturing of these distillation columns?

A: Our columns are built in compliance with leading design standards such as ASME, DIN, and IS. This assures customers of high-quality manufacturing, safety, and performance benchmarks recognized worldwide.Q: How can PLC control enhance column operation?

A: PLC control offers automated management of process variables, including temperature, pressure, and flow rates. This ensures precise regulation, improves process consistency, and allows for convenient monitoring and adjustment to meet operational requirements.Q: What is the typical service life and warranty provided with these columns?

A: Each column is engineered for a typical service life of 1015 years and comes with an 18-month warranty, ensuring customers benefit from long-term reliability and support post-installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Distillation Column Category

Distillation Column

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

Warranty : 18 month

Stainless Steel Distillation Columns

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free