Carbon Filters For Etp

Price 100000 INR/ Unit

Carbon Filters For Etp Specification

- Resistance

- <50 pa

- Efficiency (%)

- 99.9

- Type

- Cylinder, Cartridge, Modular

- Material

- Activated Carbon, Steel/FRP Casing

- Thermal Shrinkage

- 1.5%

- Working Temperature

- Up to 120C

- Application

- Effluent Treatment Plants (ETP), Water Purification, Industrial Filtration

Carbon Filters For Etp Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 4-8 Week

About Carbon Filters For Etp

Carbon Filters

With a passion to engineer flawless chemical equipment for our valued clients from Africa, the Gulf, Sri Lanka and Bangladesh, we introduce this promising range of ETP Carbon Filters. Precisely manufactured for extensive application in gas, liquid and air filtration processes of the industry, these filters are preferred over identical alternatives, available in the market, owing to their sturdy construction and enhanced operational life. These filters are designed to eradicate chlorine, organic matter, odor and color from the feed water by allowing for minimum drop in pressure. Post-engineering, we ensure to quality check these Carbon Filters only to maintain their compliance with SS304 and SS316 standards of the industry.

Features:

- Trouble-free operation

- Least maintenance

- Optimum flow rate

- Maximum functional life

Reliable Filtration for Industrial Applications

Our carbon filters are engineered to meet the demanding requirements of effluent treatment plants and water purification systems. With advanced activated carbon media and resilient steel/FRP casings, these units provide high-efficiency contaminant removal, even under elevated temperatures, making them a trusted solution for industrial and municipal customers.

Versatile Design Options

Choose from cylinder, cartridge, or modular designs to suit specific filtration setups and space constraints. Each filter is meticulously constructed for durability, consistent performance, and easy integration into existing ETP and industrial filtration infrastructures.

FAQs of Carbon Filters For Etp:

Q: How do carbon filters achieve 99.9% efficiency in effluent treatment plants?

A: Carbon filters utilize activated carbon media which adsorbs contaminants, ensuring thorough removal of impurities and pollutants. Their advanced design effectively captures even trace amounts, resulting in 99.9% filtration efficiency.Q: What makes these carbon filters suitable for high-temperature operations?

A: The filters are built to withstand temperatures up to 120C, with activated carbon and steel/FRP casing materials selected for their heat resistance and durability, ensuring stable performance under demanding conditions.Q: When should carbon filters be replaced in an ETP system?

A: Carbon filters should be replaced when there is a noticeable reduction in flow rate or filtration effectiveness, or based on scheduled maintenance intervals as recommended by your systems operational guidelines.Q: Where can these carbon filters be used besides ETPs?

A: Apart from effluent treatment plants, these filters are excellent for water purification processes and various industrial filtration applications including chemical, pharmaceutical, and food processing sectors.Q: What is the process for installing cylinder, cartridge, or modular carbon filters?

A: Installation involves connecting the filters to your treatment systems filter housings, ensuring correct fit and sealing. Modular designs offer added flexibility, allowing expansion or customization based on purification needs.Q: How does thermal shrinkage 1.5% affect filter performance in industrial settings?

A: Low thermal shrinkage ensures that the filter maintains its structural integrity and filtration efficiency under fluctuating temperatures, reducing the need for frequent replacements or maintenance.Q: What are the key benefits of using activated carbon filters with steel/FRP casings?

A: They offer superior contaminant removal, high operational reliability, resistance to corrosion and thermal stress, and long service life. These features directly enhance the quality and safety of treated water in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Category

Nutsche Filter

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel (SS304, SS316), Alloy, Hastelloy

Application : Pharmaceuticals, chemicals, dyes, food, and beverages

Thickness : 6 mm to 12 mm

Cartridge Filters

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Carbon Steel

Application : Industrial

Product Type : Cartridge Filters

Thickness : 30 Micrometers (um)

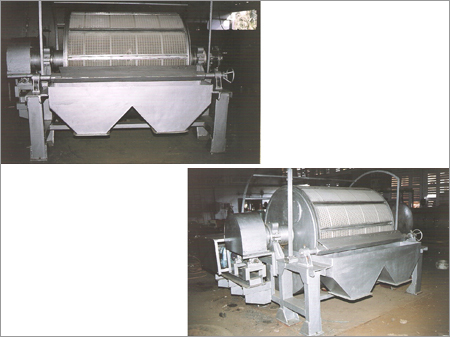

Rotary Vacuum Drum Filter

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel / Mild Steel / Polypropylene lining

Application : Industrial filtration, wastewater treatment, chemical, pharmaceutical, mining

Carbon Filter For ETP

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Application : Industrial

Product Type : Carbon Filter For ETP

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free